The world of modern fashion is no stranger to experimentation, but few garments blend history and innovation as seamlessly as the chainmail dress. What once existed only as a protective shield has evolved into a symbol of bold expression and subtle artistry. Today, designers are reinterpreting this ancient technique into garments that balance strength with beauty. The manufacturing process is not just about connecting metal rings; It is a careful blend of tradition, aesthetics and engineering.

Understanding how a chainmail dress is made requires examining the materials, design planning, and craftsmanship behind each linked piece. Each step contributes to a garment that is both visually appealing and structurally sound, reflecting the growing understanding of metal crafting in a modern way.

Historical Roots of Chainmail Construction

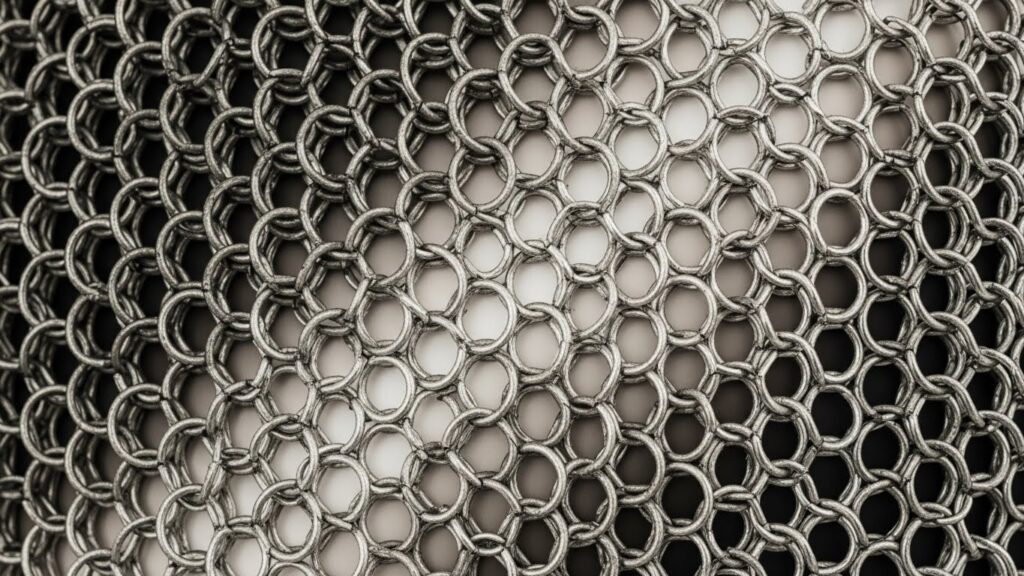

chainmail originated centuries ago as a form of armor designed to protect warriors in battle. The strength comes from thousands of interconnected metal rings that distribute power throughout the body. While the purpose has changed dramatically, the basic technology has remained largely unchanged. Designers still rely on connectivity and flexibility, but now prioritize comfort and visual flow over security.

The transition from armor to costume reflects fashion’s ability to reinterpret historical elements. The modern chainmail dress borrows this heritage and redefines it through sophisticated silhouettes and artistic intent. This historical influence adds depth and authenticity, making the garment more than a trend – it becomes a wearable heirloom.

Materials Used in Modern Chainmail Dress

Material selection is the basis of any piece of chainmail. Traditional armor relied on iron or steel, but modern fashion has a wider palette. Aluminum is often used for its lightweight nature, while stainless steel provides durability and shine. Some luxury designers also use brass, copper or precious metals to add exclusivity.

The chosen material affects not only the appearance, but also the durability. A well-made chainmail dress should move naturally with the body while avoiding stiffness or discomfort. Advances in metallurgy and finishing techniques now allow designers to combine strength with softness, reinforcing the role of luxury design in modern interpretations.

The Importance of Ring Size and Shape

In addition to the choice of material, the size and shape of each ring play an important role. Smaller rings create a dense, smooth surface that drapes beautifully, while larger rings have a more open, sculptural look. Designers experiment with circular, oval or even custom-cut shapes to achieve specific textures and patterns.

Precision is important at this level. Uniformity ensures balance and symmetry, while intentional variety can create visual interest. The construction of a chainmail dress depends heavily on these decisions, as the ring ratio directly affects flexibility, weight distribution and overall comfort.

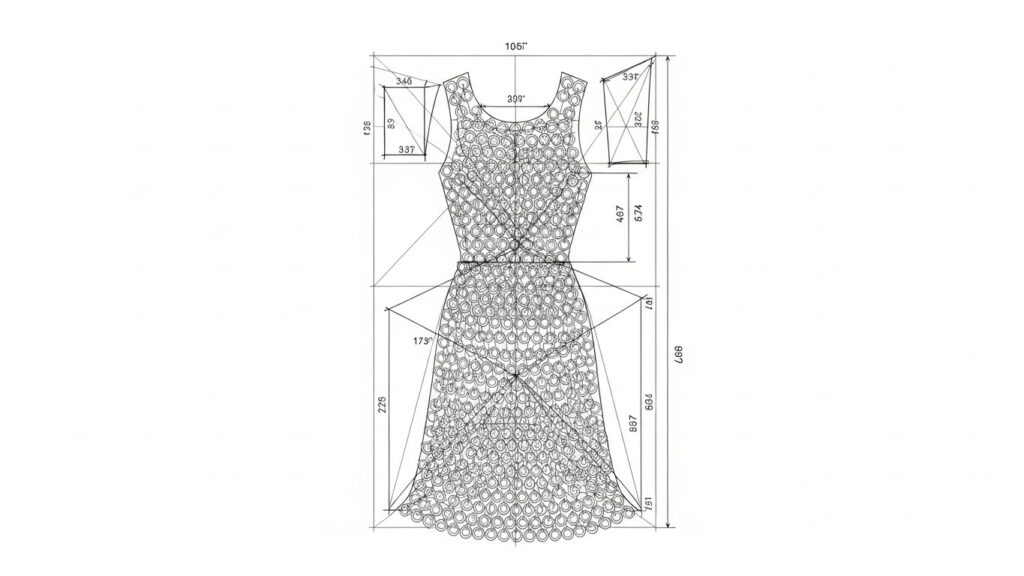

Design Planning and Pattern Creation

Before assembly begins, designers map out the structure of the garment. This step is similar to pattern drafting in traditional sewing, but with added complexity. Instead of fabric panels, the designer calculates how thousands of rings will adjust to follow the body’s contours.

The process is a form of fashion engineering, requiring mathematical precision and creative vision. A chainmail dress must take into account stretch, gravity and movement, to ensure that the final piece fits the wearer correctly. Failure at this stage can compromise the fit, making planning one of the most important steps.

Handcrafting the Chainmail Structure

The assembly process is where true craftsmanship shines. The rings are opened, joined and closed individually, often by hand. This careful process can take weeks or even months, depending on the complexity. Each connection must be secure to maintain structural integrity while allowing fluid movement.

Artisans rely on patience and perseverance, qualities that are central to metalwork. In high-quality chainmail dresses, no separate rings are present; Each element supports the whole. It is this interdependence that gives the garment its unique balance between strength and beauty.

Achieving Flexibility and Comfort

Comfort is a crucial challenge in chainmail fashion. Designers should ensure that the garment fits the body rather than restricting it. Technologies such as varying ring density in different areas provide greater flexibility where movement is essential, such as the waist or shoulders.

Modern linings or integrated fabric panels are sometimes added for comfort and delicacy. These innovations demonstrate how a chainmail dress blends ancient technology with modern needs, solidifying its place in fashion engineering rather than costume design.

Finishing Techniques and Surface Treatment

Once the garment is assembled, it undergoes a finishing process to improve its appearance and durability. Polishing removes rough edges, while coating can prevent tarnishing or oxidation. Some designers intentionally abandon raw finishes for a more industrial aesthetic, while others aim for a mirror-like sheen.

These finishing choices define the garment’s personality. A sophisticated chainmail dress reflects meticulous attention to detail, which is in line with the expectations of luxury design consumers who value both aesthetics and longevity.

Key Elements in Chainmail Dress Construction

| Element | Purpose | Impact on Final Garment |

| Material Selection | Determines weight and durability | Comfort and visual appeal |

| Ring Size | Controls texture and drape | Flexibility and movement |

| Pattern Design | Shapes the garment | Fit and silhouette |

| Assembly Method | Links all components | Structural strength |

| Finishing Process | Enhances surface quality | Longevity and style |

This table highlights how each stage contributes to the overall quality and functionality of the garment.

Quality Control and Wearability Testing

Before a garment hits the runway or market, it is tested to ensure durability and comfort. Designers examine movement under stress points, closures and wear. Any weak connections are reinforced to prevent failure during use.

Professionally designed chainmail dress reflects strict quality control. This step ensures that the garment functions as intended, whether it is featured in a high fashion editorial or worn at special events. Such testing underscores the technical expertise involved in creating wearable metal art.

The Role of Craftsmanship in High Fashion

Craftsmanship is what separates luxury fashion from mass production. In chainmail garments, this difference is even more pronounced due to the labor-intensive process. Each piece represents hours of skilled manual labor, making it a testament to the artisan’s dedication.

The enduring appeal of the chainmail dress lies in this human touch. While machines help prepare materials, assembly remains deeply rooted in craft. This connection between maker and material elevates the garment above trend-driven fashion.

Conclusion

The creation of chainmail clothing is a journey through history, design and innovation. From choosing materials to assembling complex structures, each step reflects precision and creativity. A well-made chainmail dress is the epitome of flexibility, artistry and modern sophistication.

As fashion continues to explore unconventional materials, chainmail stands as a powerful example of how ancient techniques can be revived through metalwork, fashion engineering and luxury design. The result is a garment that challenges convention while celebrating timeless skill.